I've been stuck on trying to figure out how to transport this thing. Although I have nearly finished the design of the actual raft, none of that makes a difference if I don't have a way to get it to and from the water. If I could just keep in in the water, I would have made it larger and would have been less restricted in it's design and features. I doubt anyone would let me just keep this thing on the riverfront or lake front property. Besides, I thing it would be great to have the capability to move it from one body of water to another so that we are not limited to one specific lake or river.

The difficulty in figuring this out has been the unknowns of how high it is going to sit above the water, it's overall weight and whether or not the pontoons will be able to support the weight of the raft on dry land. This will be different than it being in the water as the downward force created by the weight of the raft will be directly on the top of the pontoons, where the runner angles (which runs the length of the pontoons and supports the deck) attaches to the pontoons and where the pontoons meet the ground. In the water, this force will be somewhat equally distributed around the circumference of the pontoon (in cross section).

Another unknown is the integrity of the connection between the pontoons and the runner angle. The manning in which I am planning on connecting the barrels together to make the pontoons is this: the bottom end of each barrel (the closed end) will be seal welded to the top end (open end) of the following barrel as pictured here:

The weight of the craft will be transferred to the points where the barrels are welded together. That is to say that the runner angle will only be welded to the barrel at these locations. This is to avoid welding the angle to the walls of the barrels where the metal is very thin. That being said, there will not be much to weld the angle to as the point where the angle and the rim of the barrels touch will be very small. With such a small amount of weld, any subtle, ongoing back and forth movement of the pontoons will cause the rims of the barrels to weaken and possibility create small tears in the barrel near the rim.

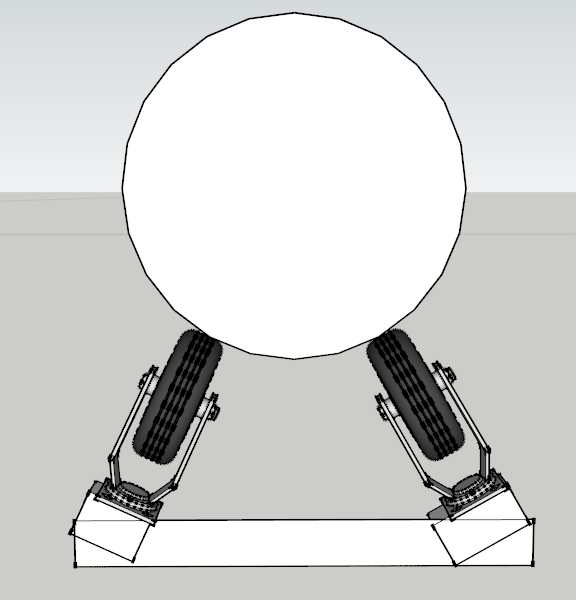

I've had a few ideas for getting the raft on and off the trailer; one of these idea is to construct a sort of conveyor made out of 12" tires as shown here:

This would comprise of individual roller assemblies that would attach to the trailer and allow the raft to roll on or off the trailer with the help of a winch .

I don't like that the weight of the raft sits on the walls of the barrels in this concept. If the raft is heavy enough, there is the possibility that some or all of the barrels could buckle where the sit on the wheels.

I would rather avoid having the raft sit directly on it's pontoons while it's on the ground or trailer. So I thought about having the wheels attached to the steel chassis between the pontoons. The wheels could either be attached directly to the frame, which would require some sort of wood ramp system on the trailer to lift the raft high enough so that the pontoons clear the wheel fenders of the trailer, or could be attached to some sort of sub-chassis which would attach to the chassis of the raft. Again, this would have to be tall enough to possession the raft above the trailer fenders. Unless this sub-chassis was permanently affixed to the raft (which is highly undesirable) there would have to be some method of getting it under the raft while it is still in the water. That could be very difficult.

No comments:

Post a Comment